MICRO PERFORATED PANELS

Murano Micro-Perforated Acoustic Panels

Murano Micro-Perforated Acoustic Panels by Sontext combine architectural elegance with advanced sound control. These panels use a fine pattern of micro-holes to achieve exceptional acoustic absorption without visible perforations, maintaining a smooth timber appearance ideal for high-end interiors.

A Subtle Acoustic Solution

Unlike traditional perforated panels, Murano Micro-Perforated Panels feature ultra-fine holes—typically less than 1 mm in diameter—spread evenly across the surface. This allows effective sound absorption while preserving the natural look of timber veneers or painted finishes. The result is an acoustically efficient system that appears completely solid to the eye.

Precision Engineering and Performance

Murano Micro-Perforated Panels are produced using computer-controlled drilling and precision finishing for uniformity and accuracy. When combined with a black acoustic fleece or air cavity, the panels can achieve NRC ratings between 0.70 and 0.90, depending on hole density and installation configuration. They are ideal for auditoriums, lecture theatres, boardrooms, and performance spaces where both aesthetics and performance are essential.

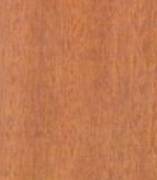

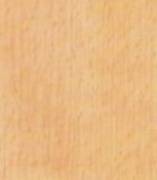

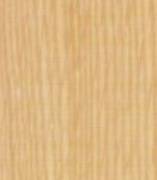

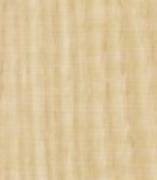

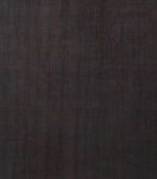

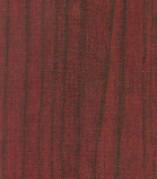

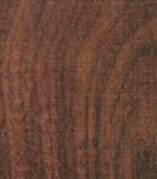

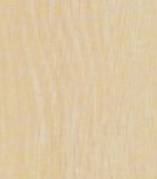

Finishes and Substrates

Panels are manufactured from MDF or plywood substrates and finished in real timber veneer, laminate, or painted surfaces. Each panel can be custom-coloured or matched to existing interior timber tones. Micro-perforated faces are available in various densities to suit specific acoustic and aesthetic requirements.

Murano Micro-Perforated Acoustic panels feature very small holes, creating the look of a non-perforated wood veneer panel. These timber panels are manufactured with small perforations to the front of the panel and larger perforations in the back of the panel; an innovative combination that absorbs sound waves efficiently. The micro perforations on the panel face are available in two hole diameters – Micro-perforated acoustic wood panels have 1.2mm holes, and Nano-perforated acoustic wood panels have 0.5mm holes. Both variations have a distinct look and have fully tested acoustic performance.

Panel construction

Both the nano- and micro-perforated acoustic panels undergo quite a different manufacturing process compared to conventional perforated panels. The front face is perforated to the selected micro hole size and the MDF backing is perforated with 9mm holes at 16mm centres. This combination provides significant acoustic performance.

Acoustic Performance

Murano micro-perforated acoustic wood panels can be installed on walls or ceilings to achieve a wide spectrum of sound absorption. It should be noted that sound absorption performance of acoustic panels is also affected by any air gap behind the installed panels as well as the type & thickness of sound absorbing insulation installed behind the panels. Sontext recommends that you consult an Acoustic Engineer in your local area to discuss the best solution for your application.

Frequently Asked Questions

What makes micro-perforated panels different?

Murano Micro-Perforated Panels use extremely fine holes that are barely visible, providing acoustic absorption while keeping a solid timber appearance.

How effective are micro-perforated panels?

When installed with an acoustic backing or air cavity, they can achieve NRC values up to 0.90, making them highly efficient for speech and music clarity.

Can micro-perforated panels be customised?

Yes, hole density, size, veneer, and finish can be tailored to suit the design intent and acoustic goals of the project.

Are Murano micro-perforated panels suitable for ceilings?

Yes. They can be installed on ceilings or walls with concealed fixings for a seamless appearance.

Where are micro-perforated panels used?

They are ideal for spaces requiring high acoustic performance with a refined, contemporary finish—such as auditoriums, theatres, and corporate interiors.

Benefits & Features

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Paint Finish

Create an inviting and unique interior space with a huge range of surface finishes, colours and groove patterns. Speak to our team about your project’s requirements.

Specifications – Murano Micro-Perforated Acoustic Panels

| Specification | Detail |

|---|---|

| Substrate | MDF or plywood core with optional acoustic fleece backing |

| Perforation Type | Micro-perforated holes typically 0.5–1.0 mm diameter, evenly spaced |

| Finish Options | Timber veneer, painted finish, or laminate |

| Standard Panel Size | Up to 1200 × 2400 mm (custom sizes on request) |

| Acoustic Performance | NRC 0.70–0.90 (system dependent) |

SUSTAINABILITY

Murano Acoustics is a division of Sontext Australia. Sontext, as a company is totally committed to sustainability: we are environmentally aware and environmentally active. Sontext is fully committed to reducing our carbon footprint and energy consumption.

We use products that range from 70% – 100% recycled materials in our manufacturing process. Our products include ODP free insulation, and it’s our aim that all raw materials meet international standards for Zero formaldehyde and no harmful VOC’s. The company will endeavour to follow best practice in line with the requirements of ISO14001:2015 and the expectations of all interested parties.

QUALITY POLICY

Murano Acoustics parent company, Sontext Australia, employs an ISO 9000:2015 Quality Management System ensuring our customers can have confidence in our ability to consistently provide the highest quality products and services.

Sontext Australia

Unit 2/16 Poa Court

Craigieburn, Victoria Australia 3064

+61 (03) 9432 2733

Sontext Middle East