PERFORATED PANELS

Murano Perforated Acoustic Panels

Murano Perforated Acoustic Panels by Sontext combine refined timber aesthetics with exceptional sound absorption. Designed for architects and builders who value both form and function, these panels feature precision-drilled perforations that improve room acoustics without compromising on visual appeal.

Aesthetic Design Meets Acoustic Function

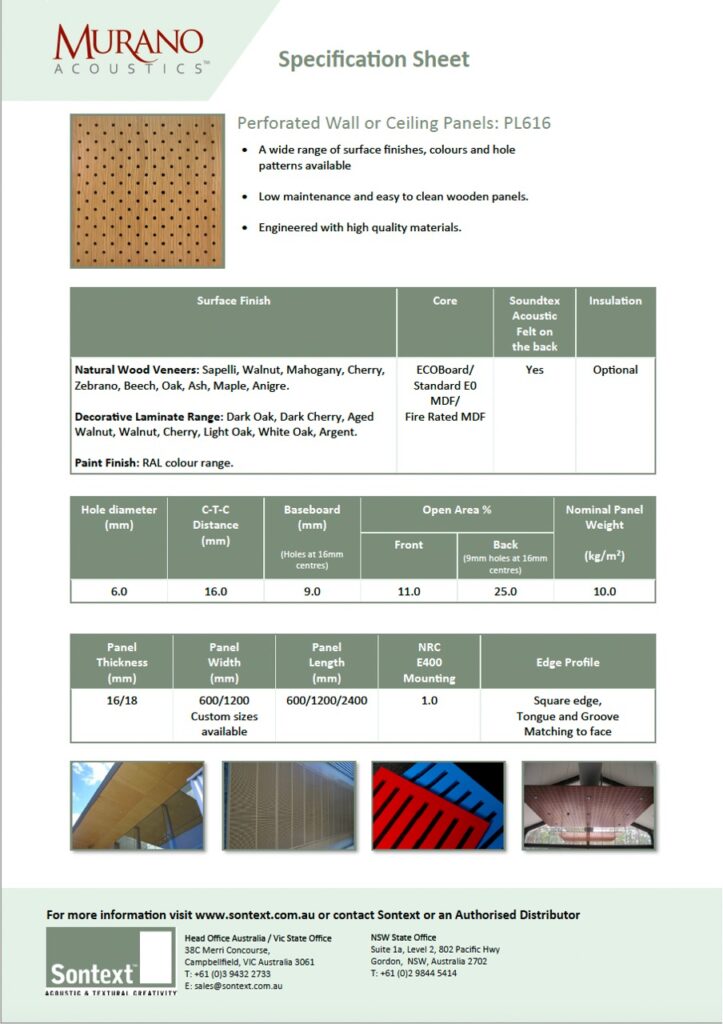

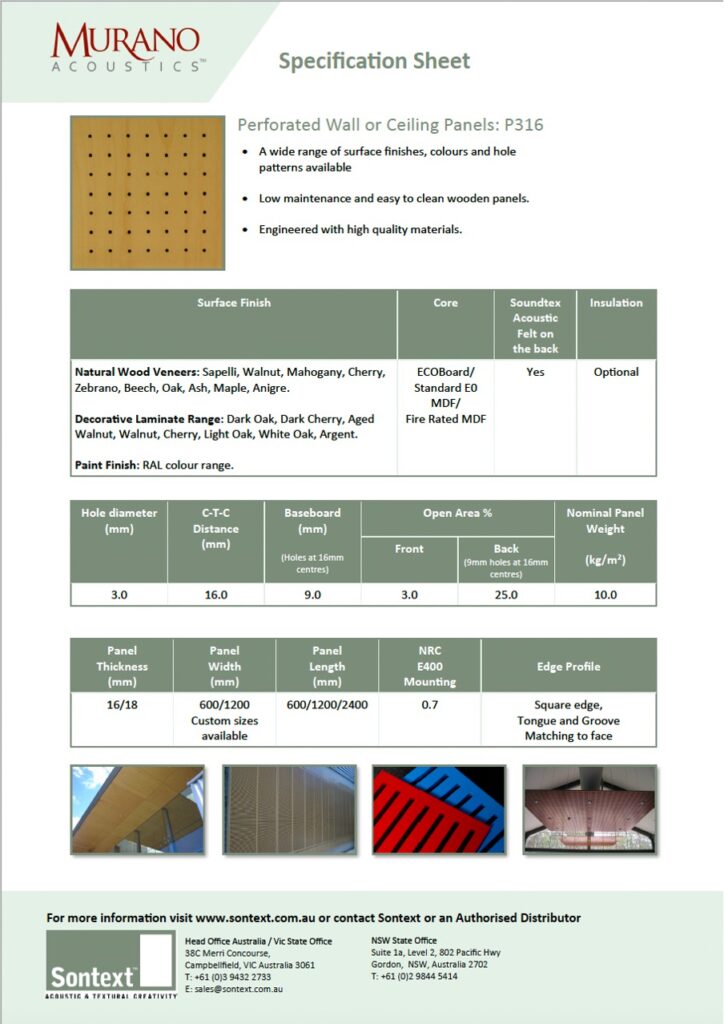

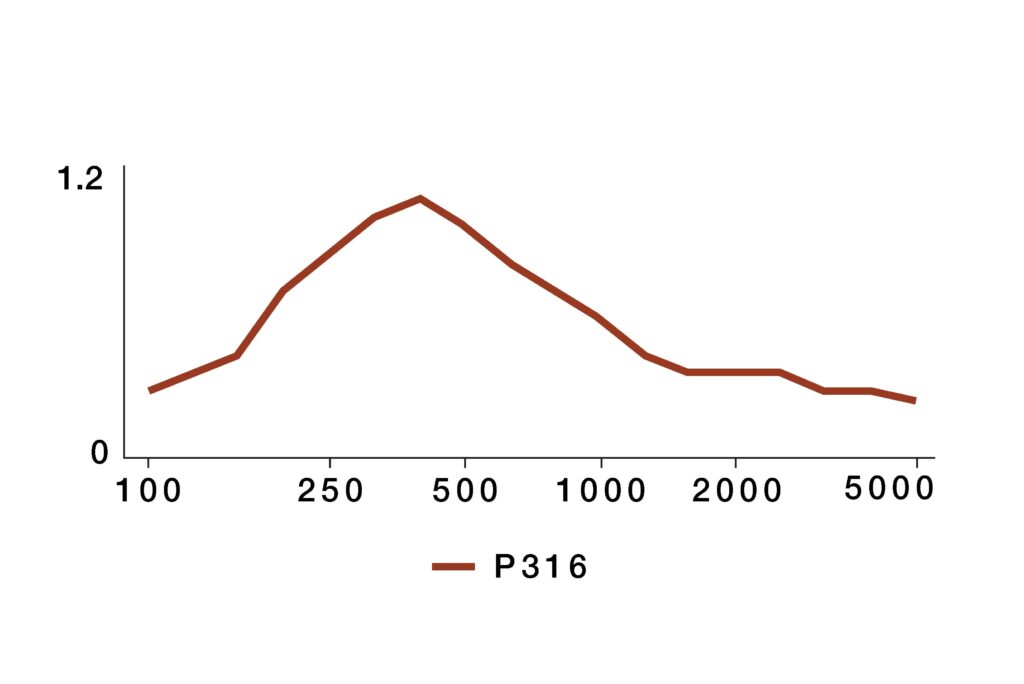

Each Murano Perforated Panel is engineered with accurate hole patterns that help control reverberation and improve speech clarity. Panels are available with a variety of perforation shapes and diameters — from fine circular holes to slots and custom designs — allowing for both visual and acoustic flexibility. When combined with acoustic backing, Murano Perforated Panels can achieve NRC ratings up to 0.90.

Materials and Finishes

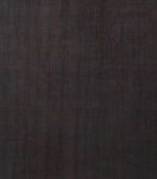

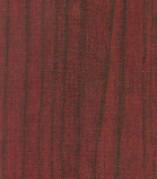

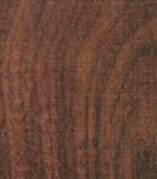

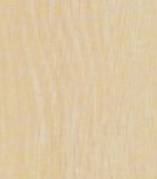

Manufactured from MDF or plywood cores, Murano Perforated Panels can be finished in natural timber veneer, decorative laminate, or painted coatings. This allows for a seamless match with interior design themes while maintaining acoustic efficiency. Fire-rated substrates and finishes are available on request.

Applications

These panels are ideal for use in offices, schools, theatres, boardrooms, and public spaces where speech intelligibility and noise control are essential. Their perforated surface absorbs reflected sound, reducing echo and creating balanced acoustic comfort throughout the room.

Murano Perforated Timber Acoustic Panels are a popular choice for designers requiring a distinct architectural finish. Our perforated wood acoustic panels reduce reverberation, reflected sound and unwanted noise across a broad spectrum of frequencies, including speech frequencies. Murano provides an extensive range of natural, quality veneers, hard wearing laminates and paint colours, allowing you to create the distinctive and inviting interior spaces.

Versatile Patterns

Murano acoustic timber panels are manufactured with “non-see-through” black SoundTex acoustic felt attached to the back. This unique backing helps to stop dust falling thorough the panel holes and also contributes to the acoustic performance. Murano Panels are made using state of the art CNC machinery to produce a large range of holes and patterns. Our standard hole perforation diameters are 3mm, 6mm and 9mm. Perforation patterns may be square or offset. (For more information on perforation hole size and pattern variations contact Sontext).

Typical Specifications

| Property | Specification |

|---|---|

| Panel Core | MDF or Plywood |

| Finish Options | Timber Veneer, Laminate, Painted |

| Perforation Diameter | 1.5mm – 12mm (custom options available) |

| Open Area Percentage | Up to 20% depending on perforation style |

| NRC Range | 0.65 – 0.90 (with acoustic backing) |

| Panel Size | Up to 2400 x 1200 mm |

.

Benefits & Features

Paint Finish

Create an inviting and unique interior space with a huge range of surface finishes, colours and groove patterns. Speak to our team about your project’s requirements.

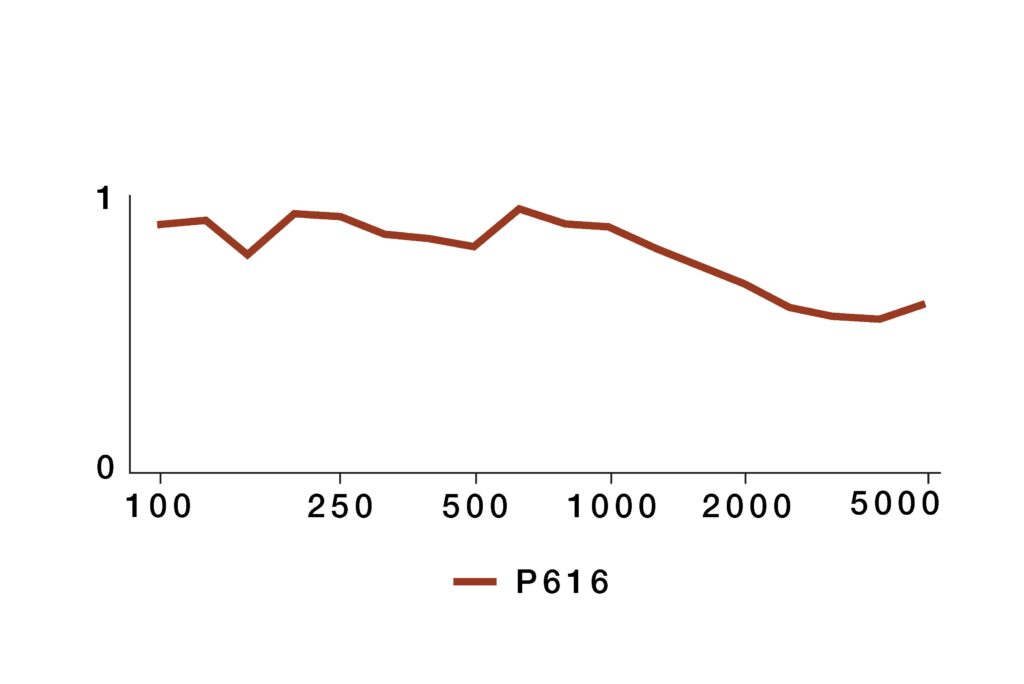

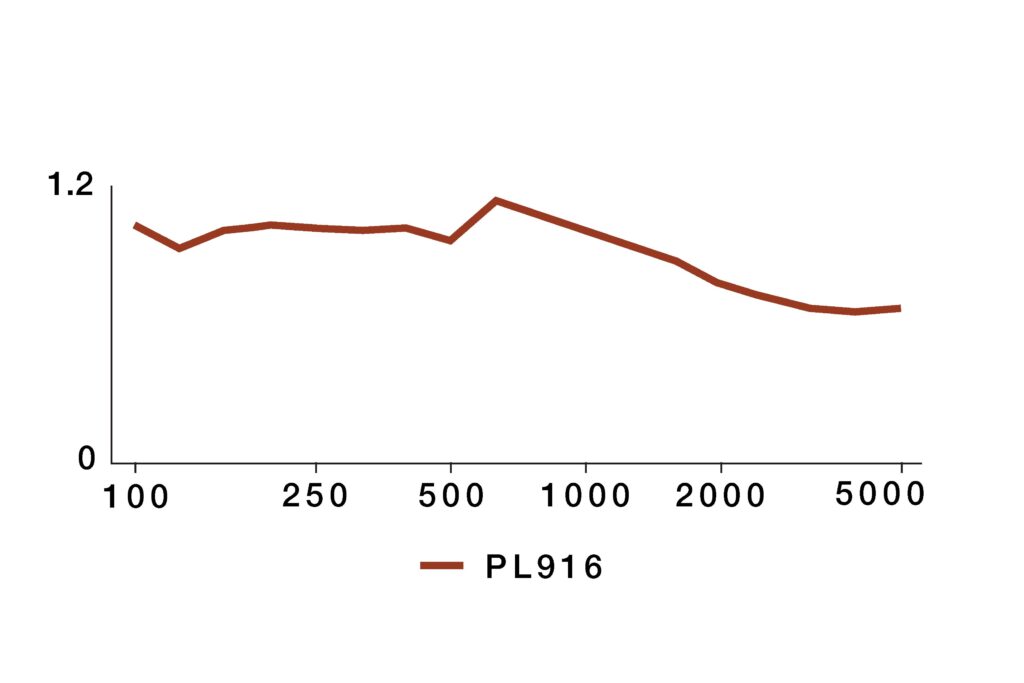

Sound Absorption

Murano Acoustic Panels are engineered to achieve the highest performance possible for a specific panel configuration. A range of materials, installation options and panel designs can be employed to ensure you achieve your objectives. Speak to our team about your project’s acoustic requirements and the range of solutions available.

Perforated Timber Acoustic Panels

Fire Safety

Murano Acoustic Timber panels are manufactured from a range of Fire rated MDF substrates. These have been tested and meet international fire standards. Speak to our experienced team about your needs and the requirements of your region.

SUSTAINABILITY

Murano Acoustics is a division of Sontext Australia. Sontext, as a company is totally committed to sustainability: we are environmentally aware and environmentally active. Sontext is fully committed to reducing our carbon footprint and energy consumption.

We use products that range from 70% – 100% recycled materials in our manufacturing process. Our products include ODP free insulation, and it’s our aim that all raw materials meet international standards for Zero formaldehyde and no harmful VOC’s. The company will endeavour to follow best practice in line with the requirements of ISO14001:2015 and the expectations of all interested parties.

QUALITY POLICY

Murano Acoustics parent company, Sontext Australia, employs an ISO 9000:2015 Quality Management System ensuring our customers can have confidence in our ability to consistently provide the highest quality products and services.

Sontext Australia

Unit 2/16 Poa Court

Craigieburn, Victoria Australia 3064

+61 (03) 9432 2733

Sontext Middle East

Level 23 - Boulevard Plaza Tower 2

Emaar Boulevard, Dubai – UAE

+971 (0) 4 409 6863

Frequently asked Questions

What are Murano Perforated Panels used for?

They are used to control reverberation and improve sound clarity in interior environments such as offices, classrooms, theatres, and boardrooms.

How do perforations improve sound absorption?

The holes allow sound waves to enter the panel, where they are absorbed by the acoustic backing or cavity behind the surface, reducing echo and reflected noise.

Can the perforation pattern be customised?

Yes, Sontext offers a variety of standard and custom perforation patterns to meet both visual and acoustic requirements.

Are Murano Perforated Panels suitable for humid environments?

Yes, moisture-resistant substrates and coatings are available to maintain stability in humid conditions.

Can Murano panels meet fire-rating requirements?

Fire-rated MDF cores and finishes can be specified to meet relevant Australian building standards.