Precision and Performance: The Science Behind Murano Acoustic Panels

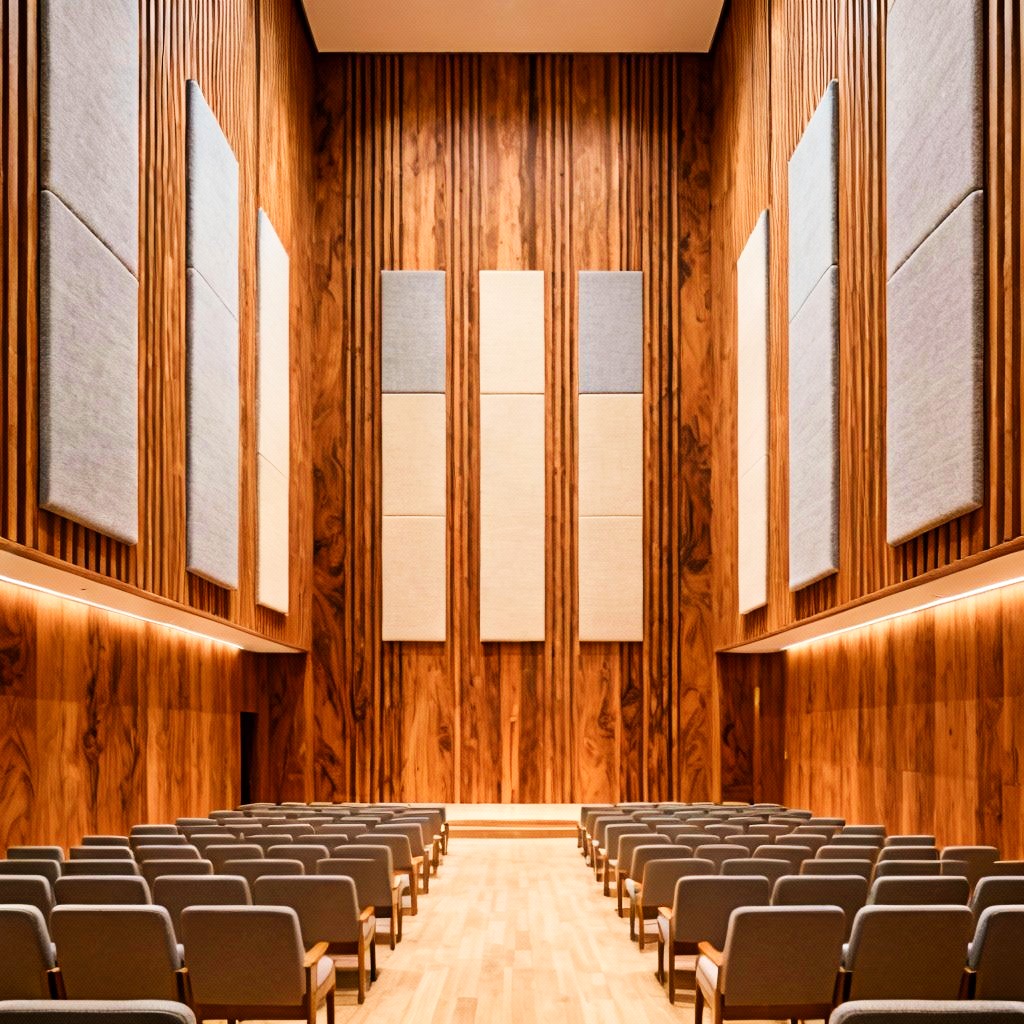

Murano Acoustic Panels combine craftsmanship with acoustic precision. Every groove, perforation, and slot is designed to achieve a specific acoustic outcome—balancing sound absorption, diffusion, and reflection. Understanding how design variables affect performance helps specifiers select the right Murano panel for each project.

The Physics of Sound Absorption

When sound waves strike a hard surface, they reflect back into the room, creating echo and reverberation. Murano Panels reduce these reflections through precisely engineered patterns that allow sound to pass through into the absorbing cavity behind the panel. This controlled interaction transforms energy into heat, reducing reverberation time and improving clarity.

Engineering for Measured Performance

Each Murano panel design is tested for its Noise Reduction Coefficient (NRC) and Sound Absorption Average (SAA). By varying parameters such as hole diameter, spacing, slot width, and backing material, our engineers can tune the panel to meet specific acoustic targets. This precision ensures consistent performance across boardrooms, classrooms, and auditoriums.

- Grooved Panels: Linear channels scatter sound evenly, achieving a balanced acoustic response.

- Perforated Panels: Micro and macro perforations maximise absorption over a wide frequency range.

- Slotted Panels: Long, narrow openings combine strong absorption with architectural rhythm.

Technical Specifications — Murano Acoustic Panel Performance

| Property | Specification |

|---|---|

| Panel Types | Grooved, Perforated, and Micro-Perforated Timber Panels |

| Acoustic Performance (NRC) | 0.60–0.90 depending on hole size, spacing, and backing configuration |

| Perforation Options | Ø 5–12 mm standard; micro-perforations Ø 0.5–1 mm available for high-frequency absorption |

| Groove Spacing | Typical 32 mm centres; custom spacing available on request |

| Backings | Acoustic fleece or 25–50 mm mineral fibre insulation to tune performance |

| Fire Performance | Tested to AS/NZS 1530.3; Group number to AS 5637.1 depending on system |

| Applications | Theatres, lecture halls, recording studios, offices, and conference centres |

Specifications are indicative. For project-specific acoustic data, please contact Murano.

FAQs

How does panel design affect sound absorption?

Perforation or groove size, spacing, and backing determine which frequencies are absorbed. Murano panels are tuned to balance clarity and warmth.

What is the difference between perforated and micro-perforated panels?

Micro-perforated panels use very small holes for broad-band absorption, ideal for areas needing discreet yet high-performance sound control.

Can Murano panels be tested for specific project requirements?

Yes. Panels can be laboratory-tested or modelled using predictive software to verify RT60 and NRC performance for each project.

Do acoustic panels block sound transmission?

No. Panels absorb internal reflections but don’t act as barriers. Use wall mass and insulation layers for sound isolation.

Are Murano panels suitable for curved or angled walls?

Yes. Custom fabrication allows panels to follow gentle curves or geometric forms for seamless architectural integration.

Next Steps

Explore Murano Micro-Perforated Panels or Murano Grooved Panels to achieve precise acoustic performance with architectural appeal. For technical advice, contact Murano today.

Need Acoustic Solutions for Your Next Project?

Speak with our team at Sontext to discuss how Serenity, Murano, or Decrasound panels can help achieve the right balance of sound control and design.

Contact Sontext TodayExplore Related Acoustic Topics

| Topic | Learn More |

|---|---|

| Serenity Fabric Acoustic Panels | View Product Page |

| Murano Timber Acoustic Panels | Explore Timber Range |

| Decrasound Polyester Acoustic Panels | View PET Solutions |

| Acoustic Design for Education Spaces | Read Blog Post |

| Acoustic Panels for Boardrooms | View Case Study |